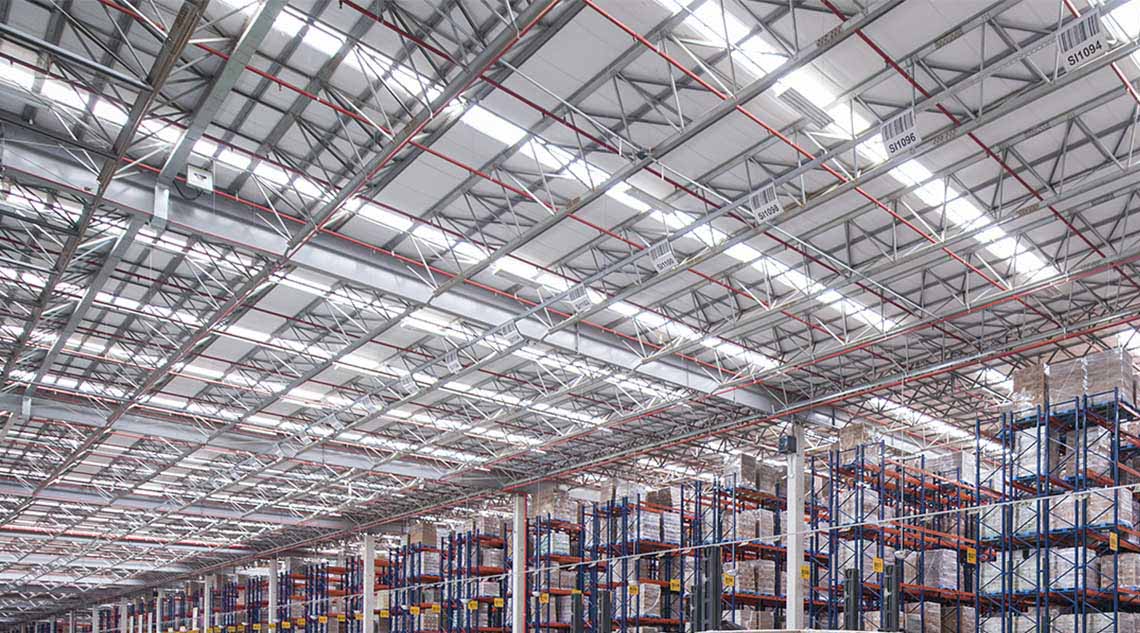

Warehouse WiFi Installation Experts

The increasing reliance on technology has necessitated the move from traditional forms of inventory management to digital solutions. Therefore, understanding the nuances of warehouse WiFi installation becomes a critical factor for warehouse operators.

Our services are essential aspects of warehouse WiFi installation, from industrial labeling and custom mounting plates to ceiling mount Intermediate Distribution Frames (IDFs) with fiber feeds, J-hook installation, conduit, and various types of pole mounted IDF racks.

Understanding Warehouse WiFi Needs

1. Importance Warehouse WiFi

Before diving into the specifics, it’s crucial to understand why a quality WiFi network is important in a warehouse setting. Modern warehouses frequently use real-time tracking systems, automated inventory management, and various IoT devices which depend heavily on WiFi connectivity. A reliable network minimizes downtime in operations, boosts productivity, and enhances overall efficiency.

2. Assessing Warehouse Layout

To begin with, analyzing the warehouse layout is crucial. A thorough site survey should identify potential WiFi dead zones influenced by shelving units, tall racks, and structural barriers. Experts should consider factors like the warehouse size, layout configuration, materials used in construction, and the potential for interference from other electronic devices.

Key Components of Warehouse WiFi Installation

3. Industrial Labeling and Custom Mounting Plates

Proper labeling of all equipment and components is vital for effective management and troubleshooting. Moreover, custom mounting plates offer better installation flexibility, especially when dealing with unique structural layouts in warehouses and identification from a distance.

Key Considerations:

- Durability: Labeling should withstand the warehouse environment, such as high humidity or temperature variations.

- Visibility: Labels should be easily readable from a distance.

- Custom Options: Creating specific mounting plates according to unique equipment dimensions ensures no time is wasted during the installation process and a clean functional application is applied.

4. Intermediate Distribution Frames (IDFs)

IDFs play a critical role in a warehouse WiFi network setup. These frames house and manage the network cables and connections, serving as a central hub for distributing internet connectivity throughout the facility. The style of IDF racks or cabinets plays a role in longevity. Warehouses with a clean environment can usually get away with open frame racks, while those with more airborne debris will require cabinets, fans, and filters. Considering environmental factors in the design is paramount.

Ceiling Mount IDFs with Fiber Feeds

Ceiling-mounted IDFs are becoming increasingly popular due to their efficient use of space, reduced cable length, and enhanced safety. By positioning the IDFs in the ceiling, you minimize clutter at ground level and keep the equipment out of reach, which reduces the risk of damage and unwanted tampering. When paired with fiber feeds, these installations not only simplify network management but also provide faster data transmission rates compared to traditional copper connections.

Benefits:

- Less Cable: Installing IDFs in the ceiling reduces the amount of fall cabling needed, which streamlines the network setup and minimizes the risk of cable-related issues.

- Increased Safety: Placing equipment in the ceiling keeps it away from traffic and prevents accidental damage, while also reducing the possibility of tampering by unauthorized individuals.

- Improved Aesthetics: Ceiling-mounted setups contribute to a tidier appearance in the warehouse, making it easier to navigate and maintain a professional look.

- Higher Bandwidth: Fiber feeds significantly enhance bandwidth capabilities, which are crucial for supporting data-heavy applications and increasing overall network efficiency.

5. J-Hook Installation

J-hooks are essential for cable management within the warehouse. They help safely guide cables across large spaces, reducing tangling and the risk of accidents.

Best Practice for J-Hook Installation:

- Spacing: J-hooks should be spaced according to cable type and weight to support the overall cabling system effectively.

- Routing: Cables should pass smoothly without sharp bends or twists to maintain signal quality.

6. Conduits

Installing conduits protects the cabling system from physical damage while also organizing the cables efficiently. Conduits can be made from materials including PVC, metal, or flexible types, depending on the warehouse environment.

Types of Conducits to Consider

- Rigid Metal Conduit (RMC): Provides excellent protection; ideal for high-impact areas.

- PVC Conduit: Lightweight and moisture-resistant; suitable for dry warehouse areas.

- Flexible Conduit: Excellent for tight spaces and complex routing, often used in environments where constant movement is required.

7. IDF Racks and Options

Selecting the right rack for your IDF setup is pivotal to the overall success of your warehouse WiFi installation. Several options are available:

Wall-Mounted Racks

Ideal for smaller installations, wall-mounted racks can maximize floor space in congested environments.

Floor Racks

For larger networks, floor racks provide increased space for cabling and equipment. They also allow for better airflow, which helps in reducing overheating.

Open Frame vs. Enclosed Racks

- Open Frame Racks: Easier access for maintenance and wiring, but less protection.

- Enclosed Racks: Offer security and protection for equipment but can limit airflow so fans and filters are needed.

8. Choosing the Right WiFi Access Points (APs)

WiFi access points are essential in covering the entire warehouse area effectively. When selecting the right APs, warehouse operators should consider:

- Density: High-density areas may require enterprise-grade APs capable of handling numerous simultaneous connections.

- Coverage Area: APs should cover expansive areas, so it's important to choose models with a wider range.

- Power Supply: Consider Power over Ethernet (PoE) capabilities, which enables the APs to operate on standard Ethernet cables, reducing installation complexity.

- Omni and Directional: Omni Antenna: Omni antennas are designed to radiate and receive signals in all directions evenly in a 360-degree horizontal plane. This makes them ideal for applications where coverage over a wide area is required, such as in a warehouse setting where devices need consistent connectivity regardless of their location and interference is not blocking line of site. They are typically mounted at a central point to maximize coverage and are easy to implement. However, the trade-off is that they often provide less signal strength at greater distances compared to directional antennas.

Directional Antenna: Directional antennas focus their signal in a specific direction, which allows for increased range and stronger signal strength in that targeted area. They are typically used in point-to-point communications, such as linking two areas or connecting devices that are far apart. By concentrating the signal in one direction, directional antennas can reduce interference from other signals and enhance performance in designated zones. While they provide excellent coverage in their targeted path, they are less effective in covering wider areas. We usually deploy these in warehouses that have floor to ceiling racks where omni can not reach without interference, generally positioned on the ends of the pathways, or in the centers facing out depending on the layout.

Installation Process: Step by Step

9. Planning and Design

A strategic plan is essential. The initial steps involve identifying where the IDF, APs, and network switches will be positioned based on the site survey.

10. Equipment Preparation

This stage involves gathering all the necessary materials, including cables, conduits, J-hooks, mounting plates, and racks.

11. Mounting and Cabling

We start by installing the J-hooks, followed by placing and securing conduits. Next, we position and mount the IDF racks and APs according to the pre-determined design while running cabling.

12. Configuration and Testing

We configure the network settings, and then test the overall performance with various scenarios. This include stress testing for bandwidth and heat mapping the entire layout ensuring there are no dead zones and we've managed complete coverage to specs.

Maintenance Tips for Your Warehouse WiFi Network

13. Regular Audits

Handing off to IT, or using our service, periodic audits should be performed to ensure the network is operating at optimal levels. Regular performance assessments will help identify any potential issues early.

14. Monitor Against Interference

Regularly gauge external interference, particularly from machinery and equipment in the warehouse that can disrupt WiFi signals.

15. Seek Professional Help

The complexity of warehouse WiFi installation necessitates consulting with professionals. We are warehouse WiFi installation experts and can help navigate specific challenges and ensure your network functions seamlessly.

Call Today for a Quote!